Acrylic & MBS Impact Modifiers and Process Aids are polymeric additives which modify a base resin during processing or in the final part.

ABOUT Impact Modifiers and Process Aids

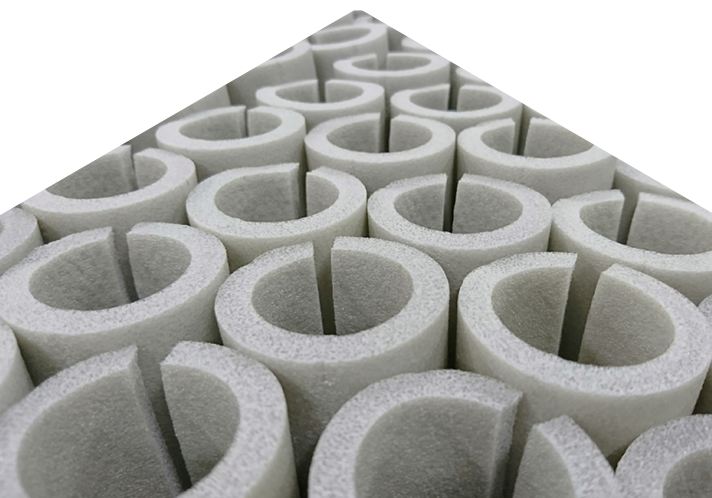

Acrylic & MBS Impact Modifiers and Process Aids are polymeric additives which modify a base resin during processing or in the final part. Process aids are active during processing in the melt phase changing the melt rheology characteristics to improve melt strength, melt elasticity etc. This can enable processing of foam parts or rendering a melt more manageable for forming the final shape. Donglin’s “Core/Shell” Impact modifiers add value to the final part by imparting toughness with more consistent processing and without drastically diminishing the base resin’s heat distortion temperature. All Acrylic impact modifiers impart toughness and are themselves very UV resistant helping render the final part useful in exterior building and construction application for instance. MBS impact modifiers are very efficient thanks to the use of butadiene rubber in the core and can be formulated to impart clarity to a PVC compound. This phenomenon is useful in packaging applications.

Contact Us

Please fill out the form and we will get back to you shortly.